3 Inch Female Socket

Contents

- Introduction

- Overview

- Importance in Various Applications

- Definition of a 3 Inch Female Socket

- What It Is

- Structural Characteristics

- Comparison with Other Socket Sizes

- Materials and Construction

- Common Materials Used

- Construction Methods

- Durability and Performance

- Applications

- Residential Uses

- Industrial Applications

- Commercial Uses

- Specifications and Standards

- Common Specifications

- Industry Standards and Compliance

- Installation and Maintenance

- Installation Guidelines

- Maintenance Best Practices

- Troubleshooting Common Issues

- Advantages of 3 Inch Female Socket

- Benefits Over Smaller or Larger Sizes

- Efficiency and Reliability

- Selecting the Right 3 Inch Female Socket

- Key Considerations

- Compatibility with Other Components

- Conclusion

- Recap of Key Points

- Future Trends and Innovations

1. Introduction

Overview

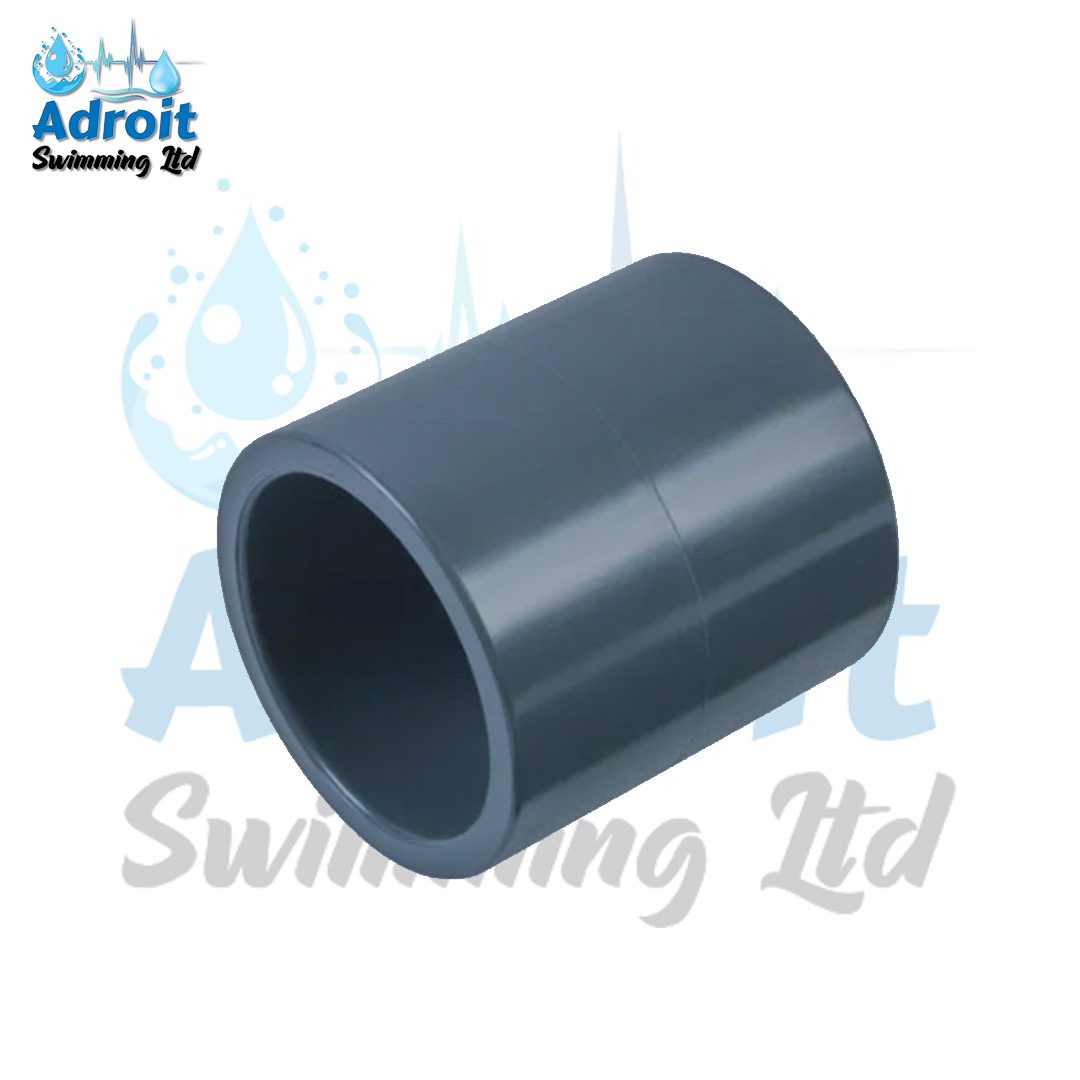

The 3 Inch Female Socket is a pivotal component in various piping and mechanical systems, widely used for its capacity to handle larger flow rates and pressures. Characterized by its internal threading, the 3 Inch Female Socket is designed to connect with male-threaded components, providing a secure and reliable connection for a range of applications. Its size, measured internally at 3 inches in diameter, makes it suitable for systems requiring robust and efficient connectivity.

Importance in Various Applications

The 3 Inch Female Socket is essential in numerous settings due to its ability to manage significant volumes of fluids or gases. In residential, industrial, and commercial systems, its role in connecting pipes, hoses, and fittings is crucial for maintaining the integrity and functionality of the system. Its reliability and performance make it a valuable component in applications requiring durable and high-capacity connections.

2. Definition of a 3 Inch Female Socket

What It Is

A 3 Inch Female Socket is a fitting with internal threads designed to connect with male-threaded components of the same size. The term “female” refers to the internal threading within the socket, which allows it to engage securely with a male fitting.

Structural Characteristics

The socket is cylindrical in shape, with its internal diameter precisely 3 inches. The internal threads are cut to match the external threads of a male component, ensuring a snug and leak-proof connection. This design is crucial for preventing issues such as leaks and ensuring the efficient flow of fluids or gases.

Comparison with Other Socket Sizes

Compared to smaller sockets, a 3 Inch Female Socket accommodates larger flow rates and higher pressures, making it suitable for more demanding applications. While smaller sockets are used for lower-capacity systems, the 3 Inch size is chosen for its ability to handle substantial volumes and pressures. Larger sockets, though capable of handling even greater capacities, may not be as practical for systems that do not require such extensive capacities.

3. Materials and Construction

Common Materials Used

- Brass: Brass sockets are popular due to their corrosion resistance and strength. They are commonly used in residential and commercial applications where moderate pressures and temperatures are encountered.

- Stainless Steel: Known for its high strength and resistance to rust and corrosion, stainless steel is ideal for industrial applications that involve harsh environments or high pressures.

- Plastic: High-density plastics offer a lightweight and cost-effective option for less demanding applications. They provide adequate resistance to corrosion and are suitable for applications where metal components might be prone to rust.

Construction Methods

The construction of a 3 Inch Female Socket involves precise machining or molding processes. Metal sockets are typically forged or cast and then machined to ensure accurate threading. Plastic sockets are usually produced through injection molding, which allows for high-volume production and consistent quality.

Durability and Performance

The durability of a 3 Inch Female Socket depends on the material and construction quality. High-quality materials and precise manufacturing processes result in a socket capable of withstanding high pressures, temperature variations, and exposure to chemicals. Regular maintenance is essential to ensure continued performance and to address any wear or damage.

4. Applications

Residential Uses

In residential settings, the 3 Inch Female Socket is often used in plumbing systems, irrigation setups, and heating systems. It connects pipes and hoses in applications where larger volumes of water or air are required, ensuring a reliable and efficient connection.

Industrial Applications

Industrially, the 3 Inch Female Socket is used in systems that handle large volumes of fluids, gases, or chemicals. It is essential in manufacturing processes, chemical processing, and water treatment facilities, where its ability to manage significant pressures and flow rates is critical.

Commercial Uses

In commercial environments, the 3 Inch Female Socket is utilized in heating, cooling, and fire suppression systems. Its robust construction allows it to handle the demands of various commercial applications, providing reliable and efficient connectivity.

5. Specifications and Standards

Common Specifications

Specifications for a 3 Inch Female Socket include the diameter (3 inches), thread type (e.g., NPT, BSP), pressure rating, and temperature range. These specifications ensure that the socket meets the requirements of the system in which it is used.

Industry Standards and Compliance

Many 3 Inch Female Sockets adhere to industry standards such as ASTM, ISO, or ANSI. Compliance with these standards guarantees that the socket meets specific performance, safety, and quality requirements, making it suitable for its intended application.

6. Installation and Maintenance

Installation Guidelines

Proper installation involves aligning the socket with the male fitting and tightening it to the recommended torque specification. Ensuring that the threads are compatible and that the socket is installed correctly is crucial to avoid leaks and ensure a secure connection.

Maintenance Best Practices

Routine maintenance includes inspecting the socket for signs of wear, corrosion, or damage. It is important to check for leaks and ensure that the socket remains clean and free from debris. Proper maintenance practices help extend the lifespan of the socket and ensure continued performance.

Troubleshooting Common Issues

Common issues with 3 Inch Female Sockets include leaks, cross-threading, and material degradation. Addressing these issues involves checking thread compatibility, tightening fittings correctly, and replacing damaged components to maintain system integrity.

7. Advantages of 3 Inch Female Socket

Benefits Over Smaller or Larger Sizes

The 3 Inch Female Socket provides a balance between size and capacity, making it versatile for various applications. It handles larger flow rates and pressures than smaller sockets while being more practical and cost-effective than larger sizes. Its design offers a reliable solution for systems requiring substantial connectivity.

Efficiency and Reliability

This socket size offers efficient performance and reliable connections, minimizing the risk of leaks and system failures. Its construction ensures a secure fit and effective transfer of fluids or gases, making it a dependable choice for numerous applications.

8. Selecting the Right 3 Inch Female Socket

Key Considerations

When choosing a 3 Inch Female Socket, consider factors such as material compatibility, pressure rating, and thread type. Ensuring that the socket meets the specific requirements of your application is crucial for optimal performance.

Compatibility with Other Components

Compatibility with other components, such as pipes and fittings, is essential. Verify that the socket’s threading and material match the specifications of the connected parts to avoid issues with leaks or improper fit.

9. Conclusion

Recap of Key Points

The 3 Inch Female Socket is a vital component in various systems, offering reliable and efficient connections for larger flow rates and pressures. Understanding its specifications, applications, and maintenance requirements is key to selecting and using the right socket for your needs.

Future Trends and Innovations

Future advancements may include innovations in materials and design, enhancing the durability and performance of 3 Inch Female Sockets. Staying informed about these developments can help in making informed decisions and optimizing system performance.

In summary, the 3 Inch Female Socket is an essential component for managing fluid and gas connections across residential, industrial, and commercial applications. Its robustness and versatility make it a valuable part of many systems, ensuring secure and effective connections.

Reviews

There are no reviews yet.